Blog

Reece Safety - Lockout Tagout and Workplace Safety Equipment

Reece Safety has been supplying Lockout/Tagout for over 16 years and we pride ourselves on providing expert advice and great service.

Our wide product range covers a whole host of safety products designed with customer safety in mind, and we are a trusted life critical safety products supplier to a wide range of industries including Construction, Power Stations, Oil and Gas, alongside a whole host of other industries.

Whether you are part of a large multinational corporation or an independent electrician, we take a no-nonsense approach to business and aim to make ordering as easy as possible.

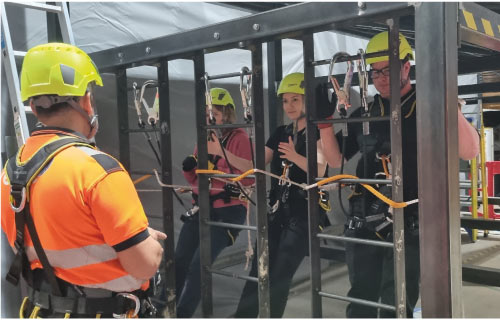

Whether you simply want to replace your Safety padlocks or review your entire process we are here to help. Our constantly extending product range is designed to keep your workplace as safe as possible, and now includes Arc Flash Clothing, Live Electrical Safety equipment and our extensive range of Key Cabinets, alongside a wide variety of Confined Space Training courses.

Based in Yorkshire, in the United Kingdom, our team have many years’ experience in lockout procedures and high voltage safety equipment, and pride themselves in helping our customers find exactly what they need and then delivering promptly, and, with £3 million of stock in our warehouse, we deliver over 90% of orders the next day.

UK

UK US

US